The Institute for Computational Design and Construction was approached by Steelcase to start a collaboration in developing novel solutions for furniture manufacturing and interiors with fiber-based material systems.

Thus, a modular system of carbon fiber modules was proposed for the micro environment. A woven carbon component with varying thickness stretches a hyperbolic paraboloid shaped acoustic fabric and can be assembled as various structures. The variation of the component in fiber layout, dimension and the different fabric configurations vary its acoustic performance, translating it directly into the aesthetic appearance of the module. A large-scale component that can be aggregated and integrates various additional functions such as lighting, ventilation and sensing capabilities was developed. Different possibilities of floor components, wall components, ceiling components and free-standing components vary in degree of invasion into existing structures when deployed.

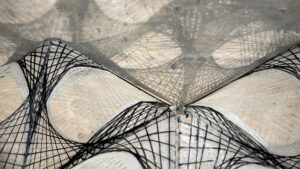

After the initial broad investigations, it was decided to continue the exploration with a focus on the development of a full-scale room divider. The wall consists of multiple similar elements that can be assembled into a larger structure. The module, made from a mix of carbon and glass fibers, can be produced in a variety of thicknesses on the same winding tools.

The size, thickness and skew of the component influences the overall geometry of the assembled wall directly. A higher shear and bigger thickness of the component result in a bigger curvature radius of the array and vice-versa.

First, by varying the starting points of the initial scaffolding fibers the overall depth of the structure is being varied. The scaffold layer creates a single surface on the top and a double surface at the bottom modules, thickening the appearance.

A secondary gradient from glass fibers varies the aperture opening of the module. This stabilizing layer from glass fiber is also the basis for the structural performance of the module.

A third layer shows a gradient from glass to carbon fiber and is overlaid on top.

The modular structure composed of 15 lightweight components became an itinerant show-piece for Steelcase’s research into novel furniture solutions under the leadership of academic research in novel additive manufacturing methods associated design principles.

PROJECT PARTNERS

Institute for Computational Design and Construction (ICD)

University of Stuttgart

Prof. Achim Menges, Moritz Dörstelmann, Serban Bodea, Chris Arias, Ramon Weber

Steelcase

Jessica Nebel, Ralf Keller, Pascal Hien, Thomas Siffer