Robotic Building aims to set the theoretical framework and practical application scenarios for a smarter built environment. Beyond technology, it looked at lifecycle and socio-economics as well as at ecological impact driven by automation in construction.

The main focus was the research and development of modular building structural components that respond to variable loading conditions and functional design parameters. The implementations invariably include the automation of construction processes. These numerically-controlled and robotically supported design-to-production and implementation chains were verified at building-component scale in the research project Scalable Porosity.

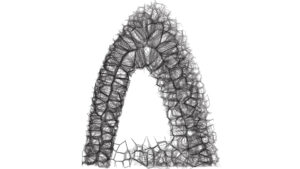

The project investigated Design to Robotic Production (D2RP) methods that utilize porosities at different scales, ranging from micro levels, as material systems, to macro levels as spatial, structural and architectural configurations.

The aim was to develop material patterns that by additive layering generate variable porosities. Due to production process constraints associated with clay printing, the research and development process for this building component, focused porosity ranges millimeter to centimeter, suitable for robotic 3D printing. The automated design-to-fabrication workflow was successfully verified by the realization of a clay-printed arch at the scale of a mid-sized architectural component.

The research into Scalable Porosity was on display at the Centre Pompidou in Paris throughout 2017 and is currently part of the TUDelft Bouwkunde collection.

Project Team

Prof. Kas Oosterhuis, Director Hyperbody TUDelft,

Dr. Ing. Henriette Bier, Dr. Ing. Nimish Biloria, Phd. Cand. Arch. Sina Mostafavi, Arch. MSc. Ana Anton, Arch. MSc. Serban Bodea