The automation of construction and operation in the built environment has led to new research and education directions in academia and new development models in the industry.

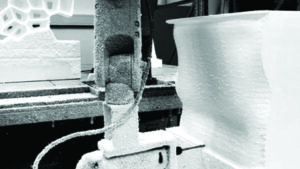

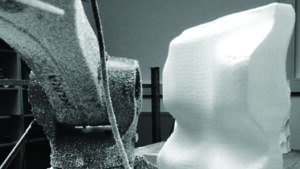

The workshop Seamless Variation addressed the link between design and fabrication through the implementation of the integrated file-to-factory chain developed by the Hyperbody Research group at the TUDelft. The workshop addressed the hierarchies present in both design and fabrication through change and differentiation.

Seamless change or transition is essential in multi-process fabrication that needs to be efficient and able to absorb differentiation. The latter is essential in composite and graded materials which promise to revolutionize Architecture Engineering and Construction (AEC). Over the course of three days, a fabrication-informed design process was introduced to the workshop students who could customize the tools provided by the workshop organizer to control robot arms in a 5-axis milling application.

The speed, precision and repeatability of industrial robots has long been utilized by the industry in processes of mass production. However, the AEC sector demands customized solutions to address the scale complexity and bespoke nature of building construction. Even though industrial robots are becoming ubiquitous in architecture schools, the integration between design (usually overly complex) and fabrication (usually inflexible to variation and customization) needs further investigations.

Computational Design and automated fabrication are thus leveraged to make complex material architectures more accessible to architects and engineers who wish to capitalize on new modes of designing and making.

Tutors: Henriette Bier, Sina Mostafavi, Serban Bodea, Ana Maria Anton